About CCPL

Since 1985, CCPL has been a trusted name in precision machined components, delivering excellence across nine countries in the automotive sector. We are driven by a relentless commitment to quality and innovation, investing heavily in cutting-edge machining technology and process automation. This dedication translates into unparalleled precision and scale, ensuring your components meet the highest standards.

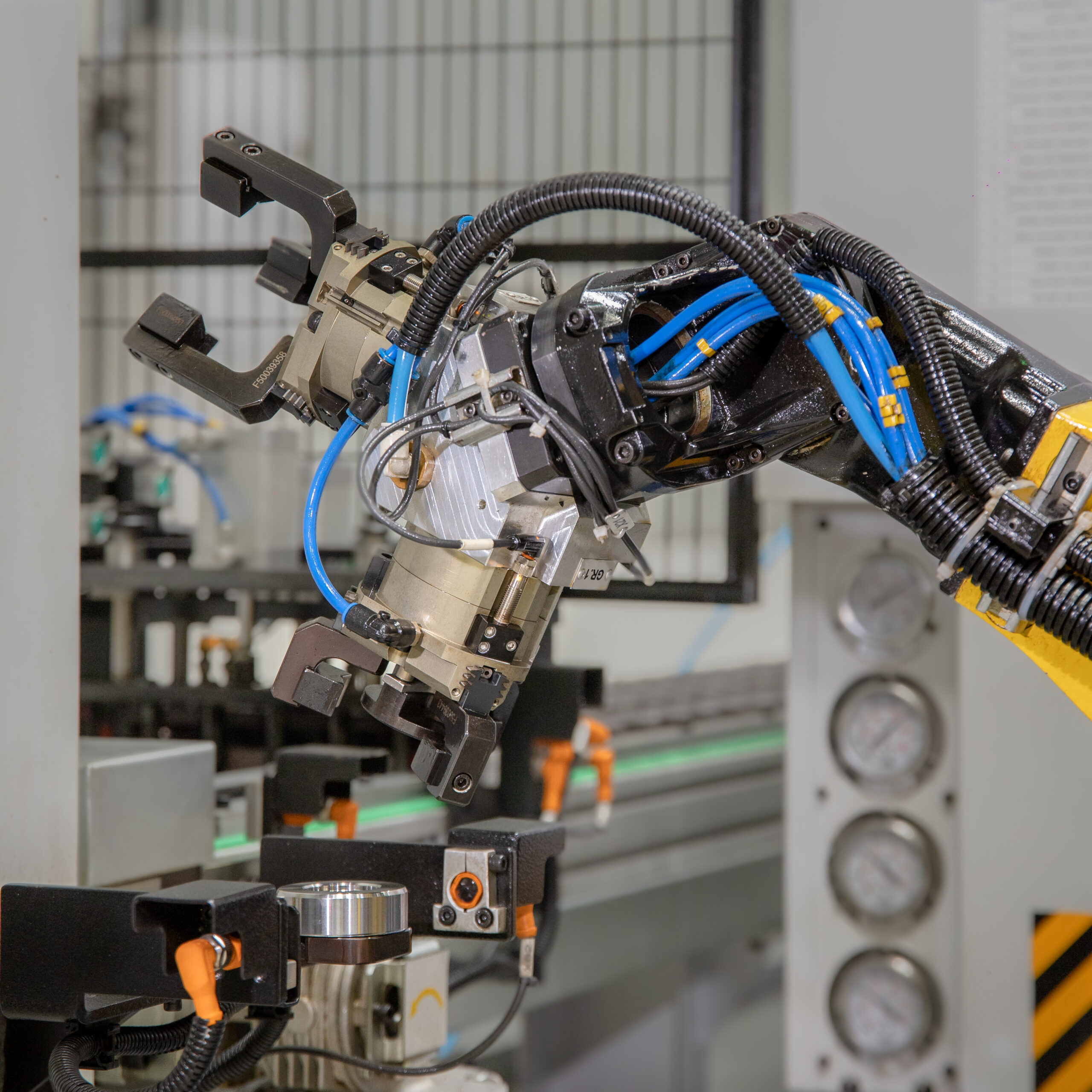

Automation is at the heart of our approach. We leverage robotics to minimize human error, guaranteeing consistent, top-notch results for every part we produce.

Our expertise extends beyond machining, with seasoned engineers and technicians applying surface treatment techniques that optimize performance and longevity.

CCPL is the go-to partner for businesses seeking affordability, sustainability, and volume. Our streamlined processes, enhanced efficiency, and cost-reduction strategies empower clients to gain a competitive edge in productivity, profitability, and market share.

Precision manufacturing is our passion, especially when it comes to high-quality reduction gearboxes. Every intricate gear and robust housing undergoes meticulous machining, ensuring precise alignment, smooth operation, and optimal performance.

Partner with CCPL and experience:

- Unwavering Precision: Components built to exact specifications, every time.

- Global Reach: Serving clients across nine countries with ease and expertise.

- Automated Efficiency: Reduced error and increased productivity for your benefit.

- Cost-Effective Solutions: Competitive pricing and strategies to maximize your budget.

- Sustainable Practices: Environmentally conscious manufacturing for a greener future.

- Unwavering Precision: Components built to exact specifications, every time.

- Global Reach: Serving clients across nine countries with ease and expertise.

- Automated Efficiency: Reduced error and increased productivity for your benefit.

- Cost-Effective Solutions: Competitive pricing and strategies to maximize your budget.

- Sustainable Practices: Environmentally conscious manufacturing for a greener future.

Our Mission

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Integer finibus varius sem, in aliquam magna sollicitudin a. Ut et dui vitae dolor scelerisque pulvinar non vel risus. Aenean ut velit hendrerit, interdum mi id, fringilla erat.

Our vision

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Integer finibus varius sem, in aliquam magna sollicitudin a. Ut et dui vitae dolor scelerisque pulvinar non vel risus. Aenean ut velit hendrerit, interdum mi id, fringilla erat.

Our commitment

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Integer finibus varius sem, in aliquam magna sollicitudin a. Ut et dui vitae dolor scelerisque pulvinar non vel risus. Aenean ut velit hendrerit, interdum mi id, fringilla erat.

Find Out More About Us

At CCPL, precision and consistency are our core strengths, backed by decades of expertise and cutting-edge automation. We deliver reliable, high-quality machined components that help our clients

stay ahead in a competitive market.

39 Years

OF OPERATION

Supplying 20

LOCATIONS ACROSS 9 COUNTRIES

20 million

COMPONENTS PER YEAR

0 Field

FAILURES

OUR MISSION

As a provider for complex steel structures, we can procure, manufacture and assemble tailor made solutions. Customers approach us because they know that we can handle and machine. assemble tailor made components and solutions driving.

OUR VISION

Our vision is to be the preferred supplier to our customers and, by being preferred supplier, to improve their competitive power. We strive to become and to remain the preferred supplier to all our customers, because this is how we can identify.

1955 - From Birth to a Period of Growth

Nippon Gakki Hamana Factory established in Hamakita-cho (present Hamamatsu city), Hamana-gun, Shizuoka Pref and production of our first product, the 125cc Yamaha motorcycle “YA-1” begins.

1970 - Creation of Demand and New Business

Yamaha Motor Canada Limited (YMCA) founded in Canada. Signed joint venture agreement with Brunswick Co. (U.S.) and Brunswick invests in Sanshin Industries.

2000 - Opening up Limitless Worlds of Potential

Yamaha builds temporary pool “Suimu 21” for the main competition pool of the 9th World Swimming Championships in Fukuoka, Japan Yamaha succeeds in the high-concentration mass culturing.

2010 - Moving further with global operations and monozukuri reforms

Medium-term management plan with central pillars of structural reform and growth strategies announced. Start of increased manufactuaring of Japanese boats to assist Great East Japan Earthquake recovery efforts.

At CCPL, we are constantly investing in cutting-edge automation and robotics, not just to boost efficiency but to minimize errors and waste. This means cleaner production, less environmental impact, and ultimately, flawless components for our clients.

Automation doesn’t stop at production. We are also investing in automated testing and inspection, ensuring we catch any issues before they reach you. This double layer of innovation guarantees unmatched quality and peace of mind.

Refer to the statistics of our company. Manufacturer’s high end manufacturing services are a perfect complement to today’s high tech industries.

We strive to be responsible manufacturers and leave a positive mark on the planet. From turning waste into resources and conserving water to harnessing renewable energy and greening our community, we are committed to minimizing our environmental impact and building a brighter future.

1

Years Experience

1 +

happy customer

1

distributor

1

factory industrial

Leadership & Advisory Team

William Charles

Anthony Jeffrey

Stephen Scott

David Nelson

Boston Lynch

Why CCPL?

- Cutting-Edge Arsenal: We leverage advanced technology and processes for high-volume production without compromising precision or quality.

- Timely Deliveries: Our focus on efficiency translates to on-time deliveries, keeping your projects on track.

- Seasoned Professionals: Our team of experienced engineers and technicians possess the skills and knowledge to bring your vision to life.

- Stress-Free Manufacturing: With our expertise at every step, you can be confident in the quality and efficiency of your project.

- Dedicated Research: We invest in cutting-edge research and development, ensuring you have access to the latest innovations and solutions.

- Future-Proof Components: Partner with us to stay ahead of the curve with reliable, innovative components.

- Trusted Vendors: We source only the highest quality parts from reliable vendors, ensuring the integrity of your entire supply chain.

- Peace of Mind: Choose CCPL and experience the security of a dependable partner, committed to your success.

Get In Touch

Quality

- State-of-the-Art: Our cutting-edge CNC machining centers and robotic systems ensure consistent accuracy and repeatability in every component.

- Automation Advantage: Automated processes minimize human error, further guaranteeing flawless results.

- 98% Acceptance Rate: Our stringent quality checks, from initial sample to final production, boast an impressive 98% acceptance rate, showcasing our commitment to excellence.

- Beyond Tradition: We go beyond standard procedures, with an extensive research infrastructure and dedicated R&D team constantly seeking innovative solutions and improvements.

- Safe & Enjoyable: We envision a future of vehicles that are safe, enjoyable, and environmentally responsible, and our high-quality components play a vital role in achieving that vision.

- Continuous Improvement: We believe in never settling for good enough. Our commitment to continuous improvement ensures that our quality standards remain at the forefront of the industry.

Demonstrating our environmental responsibility, and adherence to sustainable practices and environmental consciousness.

Our commitment to a robust quality management system, ensuring consistent quality across all aspects of our operations.

Testimonials

“ During the time I have worked with SCG on this project, I have found Mike Campbell and his team to be highly knowledgeable and results-driven. Based on preliminary pilot testing and a strong understanding of subsurface. conditions, in particular fractured bedrock environments. ased on their work on this project. "

Derek AuCoin

Defence Construction Canada

“ For over 10 years working with SCG Industries on environmental contaminated sites they have continuously demonstrated excellent technical ability while ensuring superior customer service. Their collaborative approach and real time flexibility in adapting to changing conditions has contributed to the success of many project goals. “

Derek AuCoin

Defence Construction Canada

“ For over 10 years working with SCG Industries on environmental contaminated sites they have continuously demonstrated excellent technical ability while ensuring superior customer service. Their collaborative approach and real time flexibility in adapting to changing conditions has contributed to the success of many project goals. “

Derek AuCoin

Defence Construction Canada

“ For over 10 years working with SCG Industries on environmental contaminated sites they have continuously demonstrated excellent technical ability while ensuring superior customer service. Their collaborative approach and real time flexibility in adapting to changing conditions has contributed to the success of many project goals. “

Derek AuCoin

Defence Construction Canada

Testing - Ensuring Flawless Quality

Perfection doesn’t happen by chance. At CCPL, we guarantee impeccable quality through cutting-edge testing and inspection systems.

- Equator™: This high-speed, automated gauging system replaced manual checks, ensuring unmatched accuracy and efficiency in our pneumatic component production. No room for error here.

- VeRa, the precision sorter: This specialized machine scrutinizes dimensions and finishes with unwavering precision, guaranteeing the highest quality standards for every component.

- Traceability is key: We track every component’s journey, from raw material to final delivery. Workforce involvement, quality checks, and even environmental conditions are meticulously recorded, building a complete picture of each product’s history.

- Individual data tags linked to a central database provide real-time records of materials, usage, and testing results. This unmatched transparency ensures you know exactly what you’re getting.

- Beyond production: We track product movement and chain-of-custody throughout the supply chain, offering streamlined processes and valuable insights for our partners.